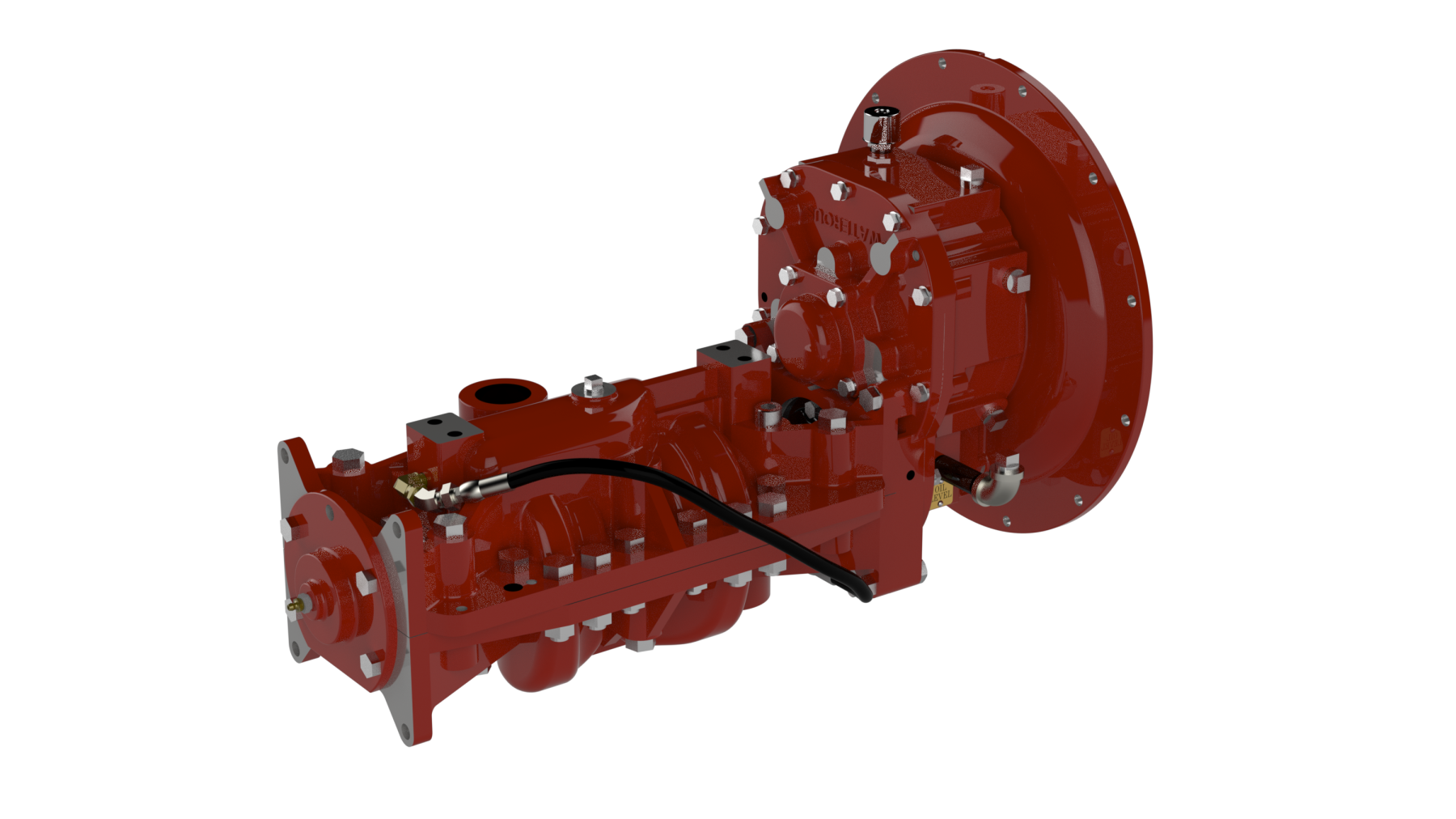

Hot Line Insulator Washing - Hot Line Washing is basically a procedure where insulators on electrical lines are cleaned with water while the electricity is energized (on). If the insulators are not cleaned, a flashover may occur causing brownouts, blackouts and damaged equipment. The Waterous CPT-4 pump is an ideal solution for hot line insulator washing. With pressures up to 800 PSI (55 bar), the insulators can be cleaned while power is still supplied to customers.

| CPT-4 PERFORMANCE | ||||||

|---|---|---|---|---|---|---|

| GPM | L/min | L/sec | PSI | Bar | kPa | MPa |

| 60 | 200 | 3 | 1000 | 70 | 7000 | 7.0 |

Specifications

- Ni-resist; special “stepped” designed wear rings reduce internal leakage & increase efficiency

- Bronze, hydraulically and mechanically balanced impellers

- Impeller hubs are “stepped” to minimize internal bypass

- High-tensile, close-grained gray iron (bronze/gunmetal optional), two-piece, horizontally-split volute body

- Adjustable braided flexible graphite (BFG) packing

- 与顺时针或counter-clockwi可用se rotation of input shaft

- T Series Transmission consists of an aluminum case with constant-mesh, stainless steel helical gears

| CPT-4 Power Line Insulator Washing | |

| Pump Information | Transmission Information |

| Dimensional Drawings

Data Sheet Instructions

Service Parts Lists Spec Sheets Performance Sheet Performance Curve |

Dimensional Drawings

Data Sheet Instructions

Service Parts Lists Preferred Specifications Specification Sheet Miscellaneous Items |

Sales/Application/Service Help

Industry-leading sales and support.

When you purchase Waterous equipment, not only do you get quality products, you get quality service. Our expert service technicians are the best in the business and they are always happy to answer any service questions you might have. The numbers for our service and training specialists are listed below for your convenience. If you have a general service question please call our main number and our staff will kindly direct you to the appropriate department.

Sales/Applications Assistance

Phone: 651-450-5234 (Press 3)

Service Assistance

Phone: 651-450-5200

Fax: 800-488-1228